- Slurry pump supplier in singapore

- Abrasive fluid transfer pump in singapore

- mud transfer pump supplier in singapore Wet crusher slurry pump / SAG mill discharge transfer pump/ Ball mill discharge transfer pump/ Rod mill discharge transfer pump/ Ni acid slurry transfer pump/ Coarse sand transfer pump/ Phosphate matrix transfer pump/ Minerals concentrate transfer pump/ Heavy media transfer pump/ dredge pump/ Fly ash transfer pump/ oily sand transfer pump/ mineral sand transfer pump/ Fine tailings/ Phosphoric acid transfer pumps/ coal transfer pumps/ Floatation transfer pump/ Sugar beets transfer pump/ Process chemical transfer pump/ Pulp and paper transfer pumps/ Lime FGD transfer pumps/ Wastewater transfer pumps

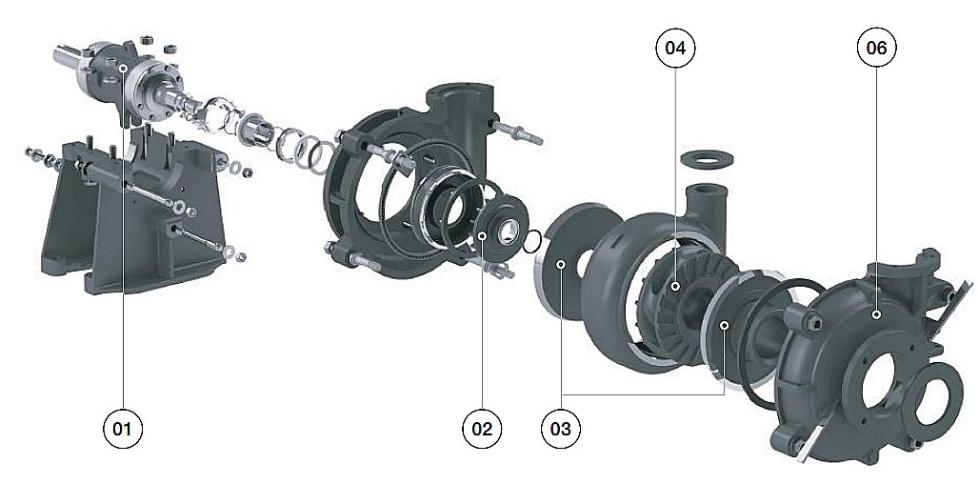

Slurry Pump

Key Specifications

Flows up to

3060 m3/hr

Pressure up to

10 Bar

Features & Benefits

1. Bearing assembly & Shaft

- The shaft has a short overhang to reduce shaft deflection and minimize vibration.

- A hardened shaft sleeve protects the shaft. Optional interchangeable heavy duty bearing assemblies.

- A one piece frame retains the bearing assembly. Impeller clearance set by adjusting the bearing assembly.

- Grease-filled piston rings prevent contaminant ingress into the bearing housing

2. Centrifugal seal option

- No gland service water required

- Reduce sleeve water

- Reduce bearing contamination or for conventional stuffing box and lantern restrictor arrangement, gland service water must be provided at a minimum of 1 bar above discharge pressure to ensure positive flow.

3. Removable liner

- Removable high-chrome, elastomer, ceramic and tungsten-coated liners can be independently replaced, minimizing maintenance costs

4. Efficient enclosed impeller

- Maximized efficiency from enclosed impeller.

- Pump-out vanes on both shrouds minimize recirculation and reduce stuffing box pressure.

- Impellers are offered in a range of materials and specifically selected to optimize your application and reduce the TOC.

- Optional high-efficiency impeller

5. Dual casing with radial split casing

- Easy disassembly of wet end

- Optional high-pressure construction

- Removable liners are positively attached with fasteners

- Interchangeable material options

6. Elastomer lined pump

- Available In both rubber and polyurethane

Construction

Alignment

Horizontal

Material

High chrome / Elastomers

Seal

Expeller seal, Mechanical seal

Coupled

Long coupled