Menu

Products

- ASME B73.1 Process pump

- ISO 5199 Process pump

- Thermoplastic process pump

- FRP process pump

- Magnetic drive sealless pump

- EN 733 centrifugal pump

- Vertical inline centrifugal pump

- Horizontal multistage centrifugal pump

- Vertical booster pump

- Split case pump

- Self-priming centrifugal pump

- Slurry pump

- Submersible pump

- Vertical submersible cantilever pump (Metal)

- Vertical submersible cantilever pump (Plastic)

- Peristaltic pump

- Air operated diaphragm pump

- Metering/Dosing pump

- Gear pump

- Progressive cavity pump

- Vane pump

- High pressure plunger pump

- Vacuum pump

- Positive displacement Lobe blower

- Hygienic centrifugal pump (FDA)

- Hygienic centrifugal pump (Helical impeller) (FDA)

- Hygienic self-priming centrifugal pump (FDA)

- Hygienic Liquid ring pump (FDA)

- Hygienic Flexible impeller pump (FDA)

- Hygienic Gear pump (FDA)

- Hygienic lobe pump (FDA)

- Hygienic progressive cavity pump (FDA)

Services

Services

Dynamic Balancing

3 Ton Dynamic balancing machine

What is dynamic balancing?

Dynamic balancing, simply put, is a method through which we balance the moving parts of a machine, or piece of industrial machinery. To do this, we rotate these parts at high speeds. When we do this, we are able to gain a measurement of the imbalance within each individual rotating component.

What are some examples of dynamic balancing?

There are many examples of how we use dynamic balancing to increase performance. Common applications for dynamic machine balancing are engine crankshafts and automobile tires. As well as balancing services for drive shafts and flywheels. These are examples from the automotive industry. Other examples include dynamic balancing of impellers, industrial fan balancing, flail rotor balancing and machine rotor balancing. We can literally perform dynamic balance analysis on any machine and its components.

Why is dynamic balancing important?

The primary goal of any equipment is to possess an operation that is free from vibration. However, vibration will always be part of any machine that rotates, and some vibration levels can be acceptable. Instead of trying to get rid of all vibration in the machinery, it is necessary to search for machinery balance as far as possible. This process minimises the vibration until there are fewer levels of noise. In addition to this, reduced vibration can extend the lifespan of your machinery. Many of our new customers say that they did not realise just how beneficial dynamic balance services were on boosting their operational performance.

What is the difference between Static and dynamic balancing?

Static balancing

- An example of balancing is static balancing. To achieve this balance, use low friction bearings to enable your machine to settle, in that the heaviest part is at the bottom. You can remove material from the lower portion or put it to the top part until it rotates on a true axis. We repeat the method of static balancing over and over again, until the point which is heavy disappears

- When a section is balanced statically, its centre of gravity is located in the axis of its rotation. This process implies that it will remain stationary at the horizontal axis, without applying a braking force.

Dynamic balancing

- We perform dynamic balancing by attaching sensors on the bearing pedestals. It enables imbalance identification on two planes for correction to occur. It uses the machines for determining the imbalance point and gives a correction. During this procedure, the sensors in the devices provide data to the computer as the machine rotates. We predetermine the rotation speed as part of the test.

- This process will offer information on the exact weight amount that needs to be added or removed to bring back balance to areas that are very light or heavy

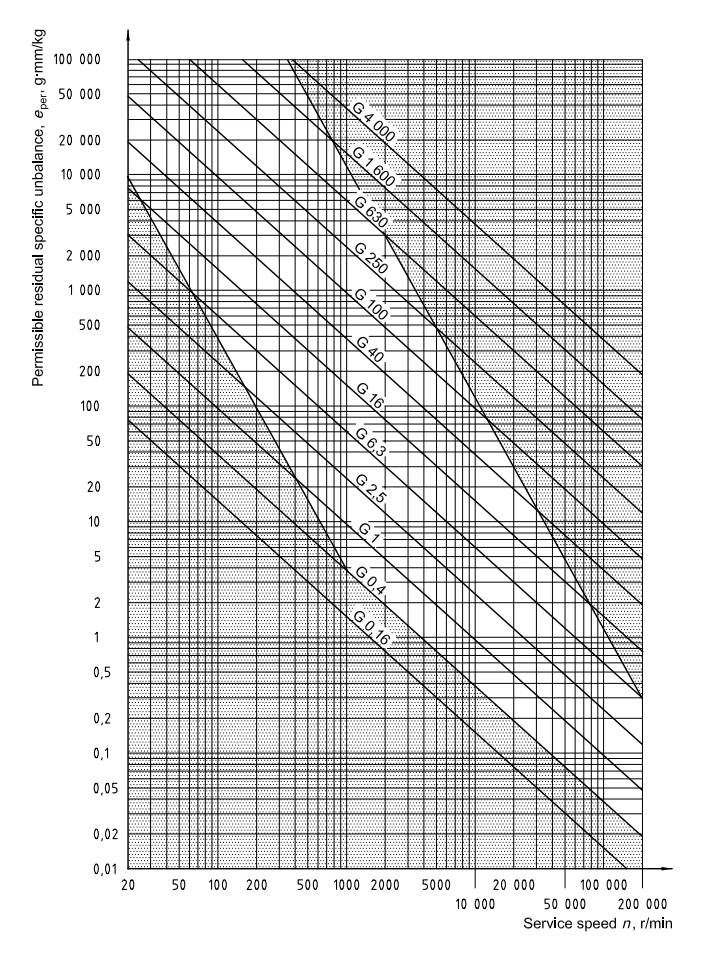

ISO 1940 – Table-1: Guidance for balance quality grades for rotor in a constant (rigid) state

| Machinery types: General examples | Balance quality grade (G) | Magnitude e per Ω mm/s |

|---|---|---|

| Crankshaft drives for large slow marine diesel engines (piston speed below 9 m/s), inherently unbalanced | G 4000 | 4000 |

| Crankshaft drives for large slow marine diesel engines (piston speed below 9 m/s), inherently balanced | G 1600 | 1600 |

| Crankshaft drives, inherently unbalanced, elastically mounted | G 630 | 630 |

| Crankshaft drives, inherently unbalanced, rigidly mounted | G 250 | 250 |

| Complete reciprocating engines for cars, trucks and locomotives | G 100 | 100 |

| Cars: wheels, wheel rims, wheel sets, drive shafts, Crankshaft drives, inherently balanced, elastically mounted | G 40 | 40 |

| Agricultural machinery Crankshaft drives, inherently balanced, rigidly mounted Crushing machines Drive shafts (cardan shafts, propeller shafts) |

G 16 | 16 |

| Aircraft gas turbines Centrifuges (separators, decanters) Electric motors and generators (of at least 80 mm shaft height), of maximum rated speeds up to 950 r/min Electric motors of shaft heights smaller than 80 mm Fans Gears Machinery, general Machine-tools Paper machines Process plant machines Pumps Turbo chargers Water turbines |

G 6.3 | 6.3 |

| Compressors Computer drives |

G 2.5 | 2.5 |

| Electric motors and generators (of at least 80 mm shaft height), of maximum rated speeds above 950 r/min Gas turbines and steam turbines Machine-tool drives Textile machines |

||

| Audio and video drives Grinding machine drives |

G 1 | G 1 |

| Gyroscopes Spindles and drives of high-precision systems |

G 0.4 | 0.4 |